Ultrasonic wire harness welding machines are widely used in automobiles, electronic appliances, motors, communication equipment, mechanical equipment, instrumentation and other fields.

Item No.:

HS-2050APayment:

T/T, Paypal, Western UnionProduct origin:

ChinaColor:

Silver and blackShipping port:

Shanghai or NingboUltrasonic Aluminum Wire Welding Metal Head Splicing Welding Machine

Specifications:

Item No

HS-2050A

Frequency

20 kHz

Power

5000 watt

Welding area

0-35 mm²

Working air pressure

0.05-0.9 MPa

Weight

55 KG

Generator size

500*400*160 mm

Machine size

600*200*260 mm

Structure:

The ultrasonic harness welding machine consists of two parts: a machine and an ultrasonic power generator.

1. Machine The machine is composed of a case, a guide post, a transducer, a pneumatic system, a PC circuit, and a bottom mold.

2. Acoustic component The acoustic component is composed of transducer and welding head. The transducer adopts piezoelectric vibrator, whose function is to convert electrical energy into mechanical vibration. The converter is analogous to the transformer in the circuit, which plays the role of mechanical damping transformation and amplitude amplification. The welding head is designed according to the welding requirements and the shape of the weldment. It also plays a role of secondary impedance transformation and amplitude amplification. In terms of structure and shape, the welding head is not complicated, but it needs the best design, the best materials and good processing technology. Welding heads with complex shapes and large sizes are difficult to design, and they are generally designed by manufacturers.

3. Air pressure system The air pressure system is powered by compressed air, through the solenoid valve switching circuit, pushing the cylinder piston to drive the welding head to move up and down. Use a pressure regulating valve to control the air pressure, and a one-way throttle valve to control the lifting speed.

Advantage:

1. One of the most important advantages of ultrasonic welding is that the temperature is low. Under the low temperature produced by the welding process, the insulation of the wire is not damaged due to the annealing and the low temperature, and the metal wire retains the original performance.

2. Ultrasonic welding is a mechanical process, no current flows through the workpiece, so the conductivity of the metal has no effect.

Workshop:

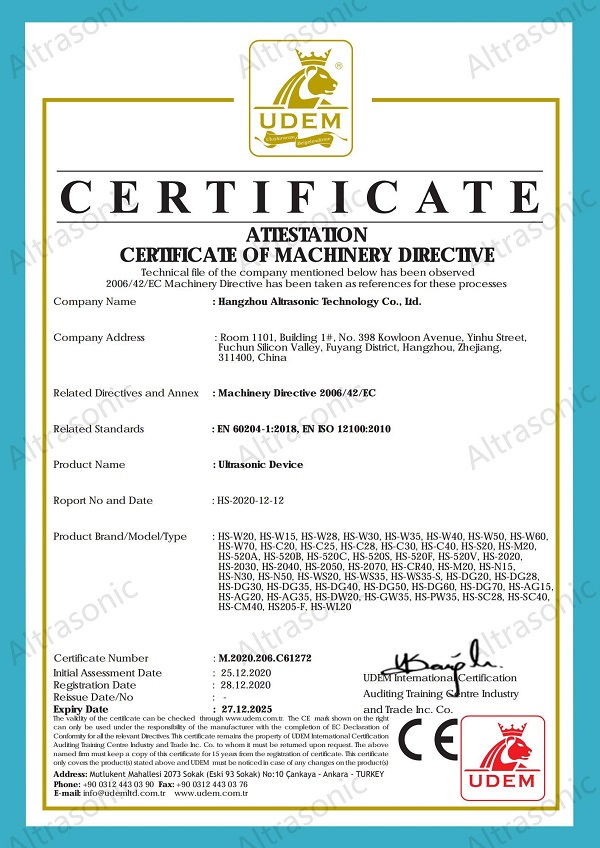

CE:

Packing&Shipping:

Shipping Port:Shanghai

Shipping Term:By express,by air,by ocean and so on.

Leading Time:Quick production leading time and fast delivery.Usually 1-3days if we have in stock.

Payment:

Previous :

Ultrasonic Wire Harness Welding Machine Car Wire Harness Parallel ConnectionNext :

20kHz 5000watt Ultrasonic Metal Welder Copper Wire Harness Welding MachineIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp