Ultrasonic terminal welding is the use of high-frequency vibration wave to make the wire to be weld on terminal.

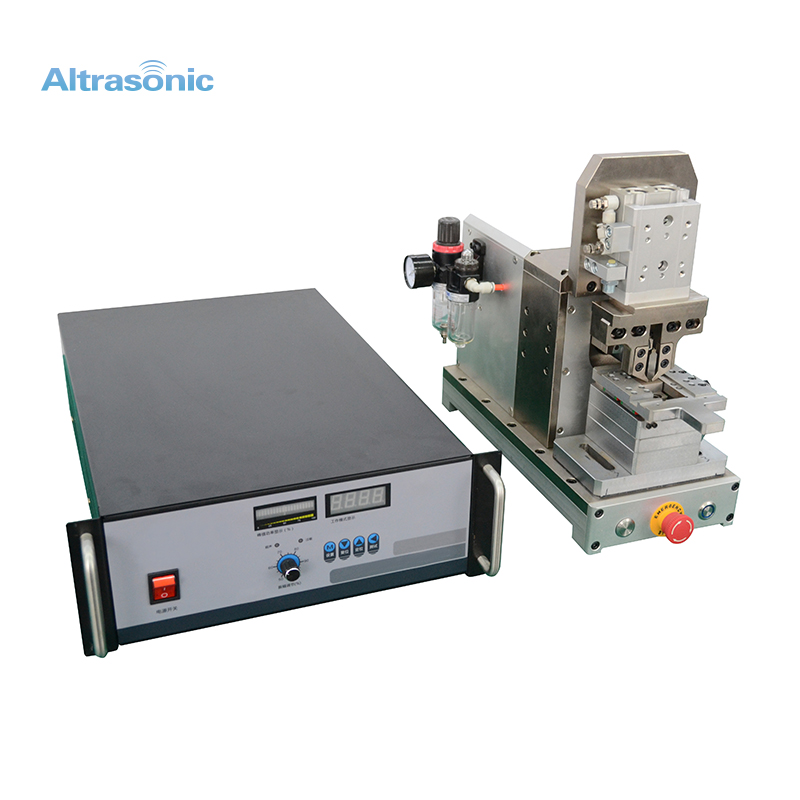

Item No.:

HS-2020-DPayment:

T/T, Paypal, Western UnionProduct origin:

ChinaColor:

SilverShipping port:

Shanghai or NingboAutomotive Terminal Welding Electrical Appliances Ultrasonic Metal Terminal Welding Device

Frequency

20 kHz

Power

2000-5000 watt

Voltage

AC 110/220±10% V 50/60±10% Hz

Weight

About 55 KG

Generator

Digital genertal

Warrty

1 Year Warrty

The welding principle of the ultrasonic terminal metal welding machine is to convert high-frequency electric energy into mechanical vibration energy through a transducer to act on the workpiece, and generate high-frequency friction between the surfaces of the two workpieces until the surfaces of the two workpieces heat up and weld together. High-tech equipment

Principle:

The welding principle of the ultrasonic terminal metal welding machine is to convert high-frequency electrical energy into mechanical vibration energy through a transducer to act on the workpiece, and generate high-frequency friction between the surfaces of the two workpieces until the surfaces of the two workpieces are heated and welded together. High-tech equipment. Parallel welding can be performed on bare copper wires. The ultrasonic welding process is a mechanical process. No current flows through the workpiece and no melting occurs. Its electrical and thermal properties are beyond the reach of other processes. Compared with fusion welding, ultrasonic welding has low consumption, long life and low labor intensity.

Application:

Ultrasonic terminal welding machine can weld wires, cables, copper stranded wires, copper braided wires (copper braids) and terminals together. This process is suitable for the automotive industry and the electronics industry. It can weld wires of different sizes to the terminals to achieve the best results in the welding of automotive wires and wires in the electronics industry.

Advantages:

1. The welding material does not melt, and the metal is not fragile;

2. After welding, the conductivity is good, and the resistivity is extremely low or nearly zero;

3. Low requirements on the surface of the welded metal, both oxidation and electroplating can be welded;

4. The soldering time is short, without any flux, gas, or solder;

5. The metal terminal welding machine has no sparks during welding, which is environmentally friendly and safe.

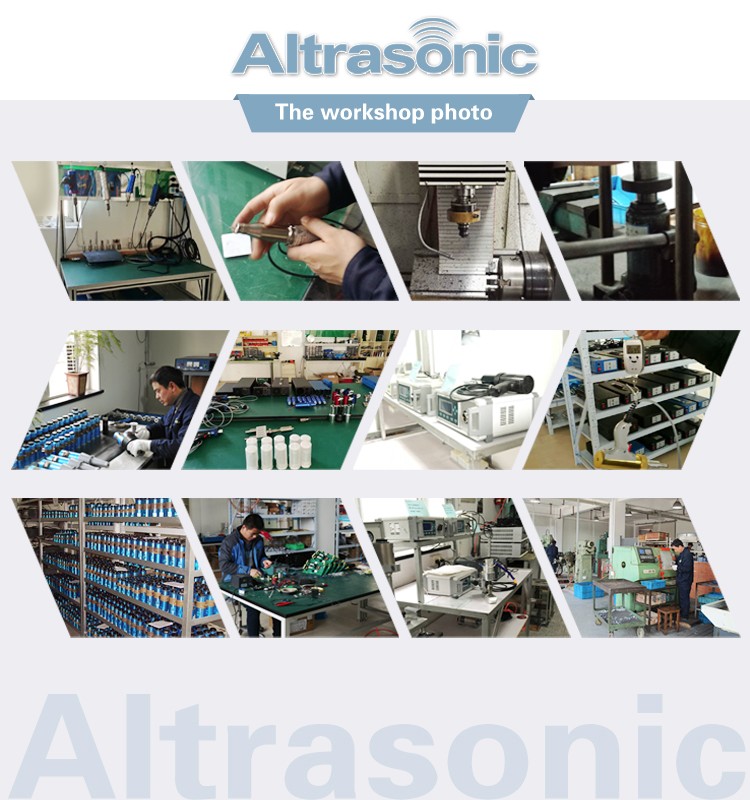

Workshop:

CE:

Packing&Shipping:

Shipping Port:Shanghai

Shipping Term:By express,by air,by ocean and so on.

Leading Time:Quick production leading time and fast delivery.Usually 1-3days if we have in stock.

Payment:

Previous :

Copper wire harness and terminal ultrasonic welding equipment Ultrasonic metal copper aluminum terminal welding machineNext :

Cable and Terminal Welder Ultrasonic Welding MachineIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp