Why is the Ultrasonic System of the Mask Machine easy to Break?

The ultrasonic system of the mask machine includes: generator, vibrator (transducer + booster), welding horn, flange, etc.

Ultrasonic generator is divided into automatic frequency tracking circuit and manual frequency modulation circuit. Experienced tuning personnel can choose manual frequency modulation generator, which is more stable and less susceptible to interference. If you are inexperienced, you can choose an automatic frequency tracking generator. You do not need to adjust the frequency, but you are susceptible to frequency changes, causing some anomalies and reporting problems.

The selection of the transducer is very important. Be sure to choose a professional manufacturer of transducers or a transducer supported by a professional ultrasonic equipment manufacturer. The transducer is a very demanding accessory, not a simple lock screw. Working, which involves structural mechanics, acoustics, frequency, amplitude, impedance, capacitance, etc., each transducer needs to undergo long-term testing to improve aging, according to the actual working conditions change, the final shape, This process can be as short as several months and as long as more than one year. (Recently, due to the shortage of transducers, many unprofessional transducers have flowed into the market, causing large-area mask equipment to fail). Therefore, you must pay attention to the selection of transducers!

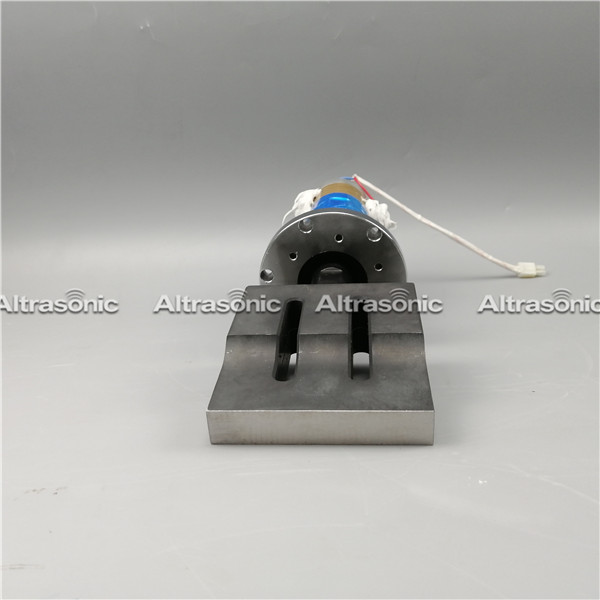

The last is the steel mold. Because of the long working time and strength of the mask machine, you should pay attention to the selection of the steel mold: choose the steel mold produced by the ultrasonic manufacturer, because the ultrasonic mold involves frequency, material, structural design, heat treatment process and other factors, such as pictures As shown, the same 110 * 20 steel mold, different materials and processing technology, the test of no-load current is better at 70-80 watts, and some reach 100-110 watts. Under the same working conditions, the empty The smaller the load current, the less likely the mold will heat up, the more durable it is, and the lower the loss on the transducer and generator.

Note on tuning: first test the system frequency to see if the frequency is within the range of use, whether the second test system's no-load current is within the qualified range, if the no-load current is too large, you need to check the transducer or mold There is no abnormality, if the mold no-load current is too large, (refer to the requirements of the generator, the general low-power models are within 0.4 amps, and the high power is within 0.8 amps). If the detection is normal, other mechanisms of the body mask machine can be adjusted through the roller Pressure, speed and other conditions to meet production requirements.

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat