Multi-Head Ultrasonic Spot Welder for Felt in Automobile Coat and Hat Stand

The automobile coat rack felt

multi-head ultrasonic spot welding machine can also be called the automobile

coat rack assembly welding equipment, which refers to the welding of the main

body of the automobile coat rack with the EPDM+PP rubber strip, and the

ultrasonic position of the automobile coat rack has multiple places. For

welding, multiple ultrasonic systems can be used for switching welding, and if

necessary, a hand-held ultrasonic welding machine can be used for repair

welding.

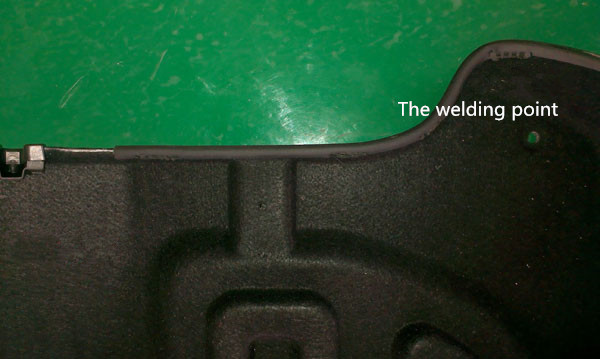

Ultrasonic welding sample of car coat and hat stand

Automobile coat rack

felt multi-head ultrasonic spot welder. Every process of welding parts is

completed in three parts in one device (eight sets of generators). Twenty

solder joints are automatically divided into three parts. The whole frame is

welded and requires a beautiful appearance. No thorns, the color is painted,

the coating is uniform, the structure is reasonable; easy to operate, debug,

repair, easy to handle; all processing beats within 60 seconds (excluding pick

and place). The number of welding points of the coat racks designed by various

automotive interior parts manufacturers is different, and the relative

parameters are also different.

Ultrasonic welding

of car coat and hat rack

Solidify the plastic

well on the car coat rack

The ultrasonic wave

of automobile coat and cap frame adopts 28KHZ frequency system and titanium

alloy welding joint material: the front door is processed and made by titanium

alloy material. After professional ultrasonic mold software analysis, it can be

reproduced after qualified parameters such as frequency and amplitude, so as to

ensure uniform amplitude of the mold and improve service life.

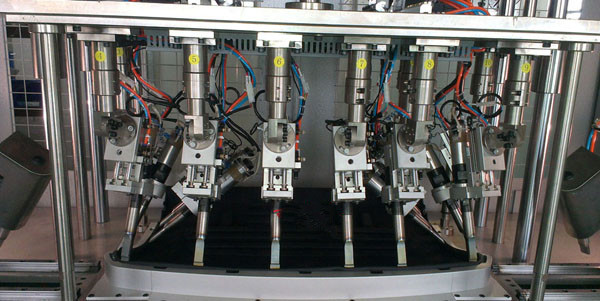

Main function of multi - head ultrasonic spot welding machine

for auto coat and hat rack

More than using high strength steel as the framework, welding

head down welding, single welding head separation control at the same time,

each ultrasonic adopts air cooling device, the limit screw can adjust the

height of the upper die, controlled by the cylinder on the plate movement, PLC

man-machine interface control, convenient debugging, and adopting the side pull

structure installation, high precision. The whole machine is easy to debug and

stable in performance. The practical model can be adjusted at will, and can

also cooperate with semi-automatic or full-automatic production.

The pushing mechanism of the equipment can be divided into

manual operation and automatic operation, manual operation is a single action,

mainly used for the debugging of the mechanism and mold. In the PLC computer

touch screen on the main operation screen, according to the welding requirements

of the workpiece welding time, curing time, delay time, pressure value to set.

Press the computer touch screen to determine automatically,

close the door (the proximity switch indicator light is on) or the safety

grating, and press the start switch (blue) left and right buttons with both

hands. The process is controlled by PLC to achieve full automatic control.

Start the upper die of the switch to perform pressure welding on the workpiece.

Production for automatic, automatic control system using programmable

controller (PLC) to control, cylinder coherent motion. Simple operation,

reliable performance, compact size, improve production efficiency and quality.

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat