Introduction of Ultrasonic Machining

Working Principle of Ultrasonic Machining

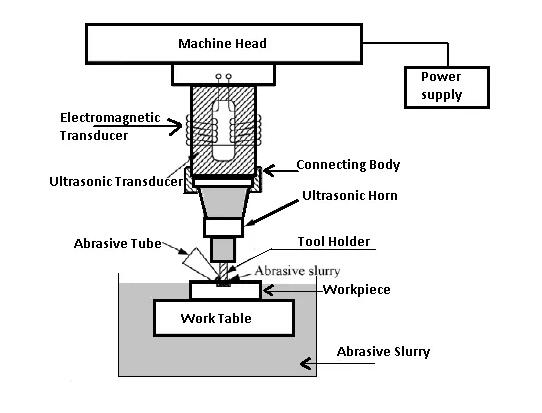

The figure shows the Ultrasonic machining operation. The electronic oscillator and amplifier, also known as the generator, converts the available electrical energy of low frequency to high-frequency power of the order of 20 kHz which is supplied to the transducer.

The transducer operates by magnetron striction. The high-frequency power supply activates the stack of the magnetostrictive material which produces longitudinal vibratory motion of the tool. The amplitude of this vibration is inadequate for cutting purposes. This is, therefore, transmitted to the penetrating tool through a mechanical focusing device which provides an intense vibration of the desired amplitude at the tool end.

The mechanical focusing device is sometimes called a velocity transformer. This is a tapered shank or called ‘horn’. It’s upper end being clamped or brazed to the lower face of the magnetostrictive material. Its lower end is provided with means for securing the tool.

All these parts, including the tool made of low-carbon or stainless steel to the shape of the desired cavity, act as one elastic body transmits the vibrations to the tip of the tool.

The Commonly Used Abrasives Are

aluminium oxide (alumina), boron carbide, silicon carbide, and diamond dust. Boron is the most expensive abrasive material and is best suited to the cutting of tungsten carbide, tool steel and gems. Silicon finds the most application. For cutting glass and ceramics, alumina is found as the best.

The abrasive slurry is spread to the work-tool interface by pumping. A refrigerated cooling system is used to cool the abrasive slurry to a temperature of 5 to 6 °C. A good method is to keep the slurry in a bath in the cutting zone.

The size of the abrasive varies between 200 grit and 2000 grit. Coarse grades are good for roughing, whereas finer grades, say 1000 grit, are employed for finishing. Fresh abrasives cut better and the slurry, therefore, be replaced periodically

Accuracy

The maximum speed of penetration in soft and brittle materials such as soft ceramics are of the order of 20 mm min, but for hard and tough materials, the penetration rate is lower. Dimensional accuracy up to t0.005 mm is possible and surface finishes down to a Ra value of 0.1-0.125 micron can be obtained.

A minimum corner radius of 0.10 mm is possible to finish machining. The range of sizes of USM machines varies from a light portable type having an input of about 20 W to heavy machines taking an input up to 2 kW.

Limitations of the Process

The main limitation of the process is its relatively low metal cutting rates. The maximum metal removal rate is 3 mm®/s and the power consumption is high. The depth of cylindrical holes is presently limited to 2.5 times the diameter of the tool.

Wear of the tool increases the angle of the hole, while sharp corners become rounded. This implies that tool replacement is essential in the production of accurate blind holes. Also, the process is limited, in its present form to the machine on surfaces of comparatively small size.

Recent Development

Recently a new development in ultrasonic machining has taken place in which a tool impregnated with diamond dust is used and no slurry is used. The tool has oscillated at ultrasonic frequencies as well as rotated. If it is not possible to rotate the tool the workpiece may be rotated.

This innovation has removed some of the drawbacks of the conventional process in drilling deep holes. For instance, the hole dimensions can be kept within +0.125 mm. Holes up to 75 mm depth have been drilled in ceramics without any fall in the rate of machining as is experienced in the conventional process.

Application of Ultrasonic Machining

The simplicity of the process makes it economical for a wide range of applications such as:

· Introducing round holes and holes of any shape for which a tool can be made. The range of obtainable shapes can be increased by moving the workpiece during cutting.

· In machining operations like drilling, grinding, profiling and milling operations on all materials both conducting and non-conducting.

· Machining glass, ceramic, tungsten and other hard carbide, gemstones such as synthetic ruby.

· In cutting threads in components made of hard metals and alloys by approximately rotating and translating either the workpiece or the tool.

· In making tungsten carbide and diamond wire drawing dies and dies for forging and extrusion processes.

· Enabling a dentist to drill a hole of any shape on teeth without creating any pain.

· Extremely hard and brittle materials can be easily machined.

· Highly accurate profiles and good surface finish can be easily obtained.

· The machined workpiece is free of stresses.

· The metal removal rate is low.

· Due to practically no heat generation in the process, the physical properties of the work material remain unchanged.

· The operation is noiseless.

· Operation of the equipment is quite safe.

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat