Ultrasonic Assembly Process

In Ultrasonic welding, high frequency sound energy is used to bring the joining surfaces of two thermoplastic parts to a molten state where they can be permanently welded together.

1. The horn, under pressure from the assembly stand, contacts one of the two mated plastic parts.

2. Vibrational energy from the horn causes the contacted plastic part to vibrate against its mate.

3. The mechanical vibration of one part against the second causes frictional heat, which melts the plastic parts at their interface and allows the two

surfaces to molecularly fuse together.

4. After a short cooling time, a permanent, homogeneous weld results.

Ultrasonic Weld Types

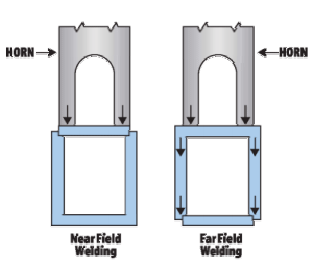

Near Field Weld (Direct): Refers to a weld where the contact surface of the horn is 1/4" or less away from the joint surface. It is important that the horn fits exactly the contour of the part to be welded.

Far Field Weld (Indirect): The distance between the contact surface of the horn and weld between the contact surface of the horn and weld joint is more the 1/4". Ultrasonic energy is transmitted through the upper portion of the part to the joint surface.

Previous :

Other Applications for Ultrasonic WeldingNext :

Ultrasonic Joint Designs© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat