For a given set of weld parameters, variations in force control that result in applying too little force reduce compression of the mating surfaces, reduce the heat generation needed for plastic melt, and result in cold or weaker welds. Similarly, force variations that result in applying too much force can cause part joints or energy directors to deform, deflect or break and may not provide ...

Development trend of ultrasonic welding technology 1. Improving welding productivity is an important driving force for the development of welding technology. There are two ways to improve productivity: firstly improve the welding deposition rate, such as three-wire submerged arc welding, the process parameters are 220A/33V and 1400A40V1100A45V respectively. The groove section is smal...

The fixture material choice will also affect how the plastic material flows at the joint interface. A soft resilient type of material will create a different flow rate than a rigid metal nest. Different fixture materials will create various frictional reactions at the weld joint. An experienced ultrasonic tool maker can assist with choosing the appropriate fixture material. Most of the time...

Many different types of materials have been used to build fixtures for ultrasonic assembly including plastics, stainless steel, tool steel, aluminum, cork, poured urethane and silicone rubber. All of these can play a role depending upon customer’s needs, but the most common fixtures include aluminum, steel and poured urethane. Poured urethane fixtures are frequently used for supporting rigi...

The use of CAD/CAM technology has greatly improved the manufacturing of contoured fixtures to support the part during ultrasonic assembly. Exact mirror replicas of the part can be created to provide excellent support to the part. Due to complex contours seen on many parts, it is recommended that the horn and fixture be purchased as a set, so proper alignment is achieved between the two. The...

The latest advances in ultrasonic welding for medical devices are driven by the need to assemble plastic parts that tend to be smaller and lighter in weight, thinner-walled, and often more contoured than in the past. A growing number of these parts also contain embedded electronics and sensors that require special care in the ultrasonic welding process. Meeting the medical device ind...

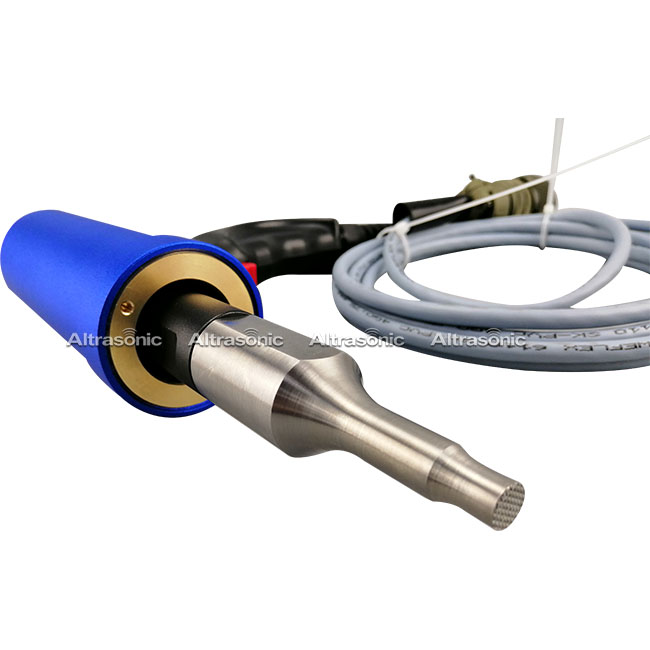

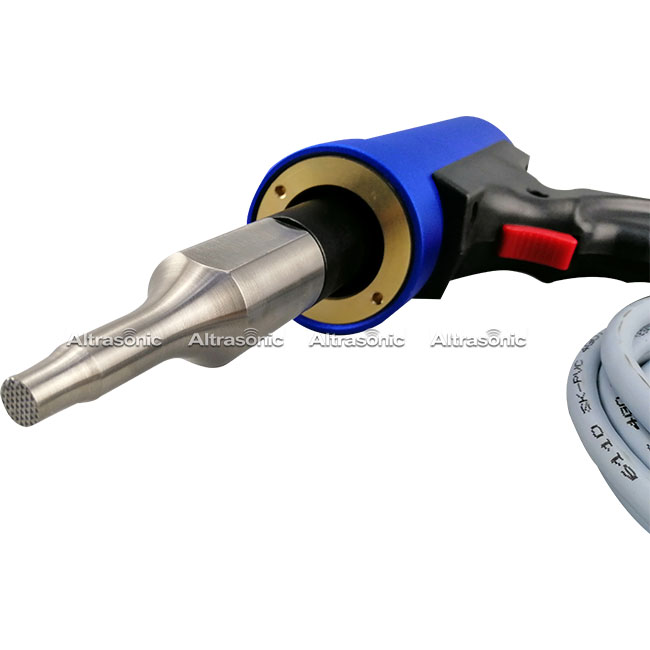

Ultrasonic Package Welding This Ultrasonic Package Welding machine is suitable for the packaging of plastic products of electronic products, with good sealing performance and high production efficiency. The machine adopts high quality piezoelectric ceramic transducer, which outputs strong and stable titanium alloy horn, square column, guide bearing. The adjustable fine adjustment device bot...

The ultrasonic welding generator produced by our company uses a self-excited circuit. When it is working, it can stably track changes in transducer parameters and maximize the performance of the plastic welder transducer. This kind of equipment adopts imported high-power tube, which is resistant to large current impact and increases the stability of the operation of the ultrasonic generator...

Categories

New Products

High Efficiency 28khz Ultrasonic Sealing and Cutting Machine for Plastic Film Packing Bag Read More

Ultrasonic Welding Generator for N95 Mask Making Analog 15k Generator Read More

40kHz 800Watt Ultrasonic Converter BNC Connect Replace Branson 4TH Read More

Processing Special Surface of Mould Amplitude Stability Ultrasonic Milling Equipment Read More

New Product Clothing Manufacturing Rotary Sealing Machine Ultrasonic Sewing Machine Read More

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat