Magical ultrasonic cutting technology

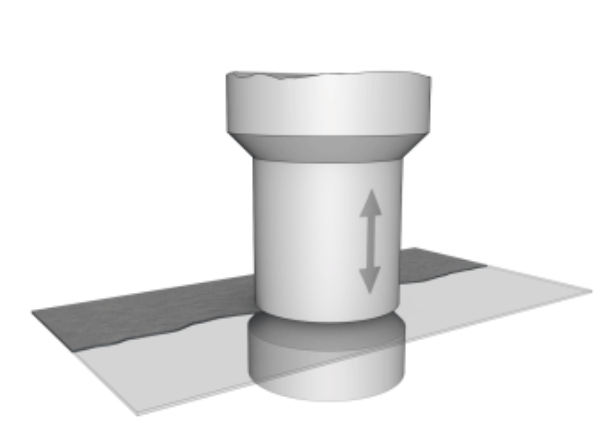

Cutting process:

Separation welding:

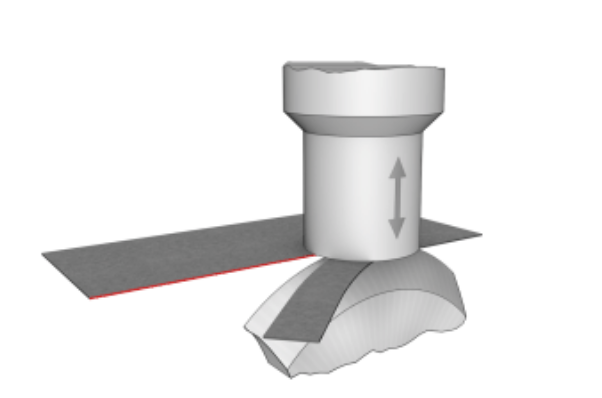

Synchronous edge cutting:

Cutting and sealing are performed and completed simultaneously. Both ends of the welding fiber can be cut simultaneously within one micron, which is a clear advantage in high-quality medical and filtration technologies.

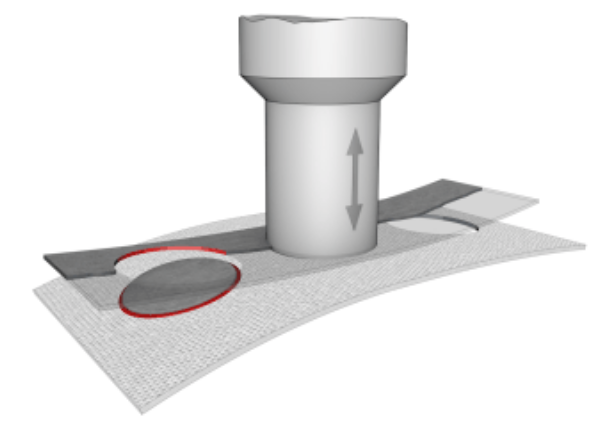

Continuous cutting and sealing:

The advantage of ultrasonic cutting and sealing technology is that it can quickly and accurately seal and cut woven and non-woven fabrics in continuous operation.

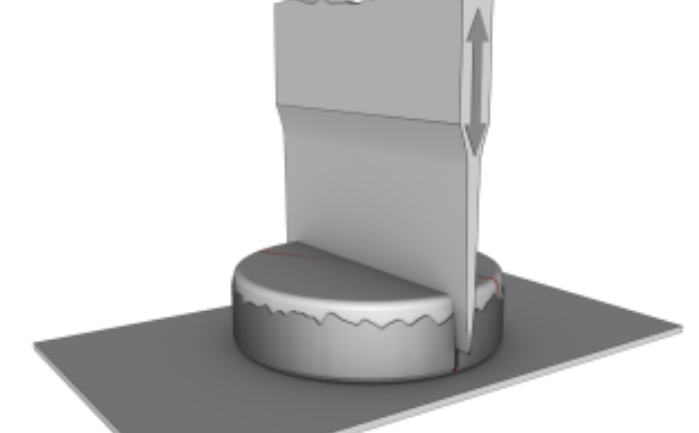

Cutting and welding:

Flexible cutting of polymer and textile components must guarantee cutting edges at the fastest speed and accuracy. Ultrasonic treatment is the ideal process in the automotive industry.

Distribution:

Ultrasound cuts the product accurately and quickly with minimal resistance through high-speed vibration, and realizes no residue, no deformation and no thermal damage on the product surface.

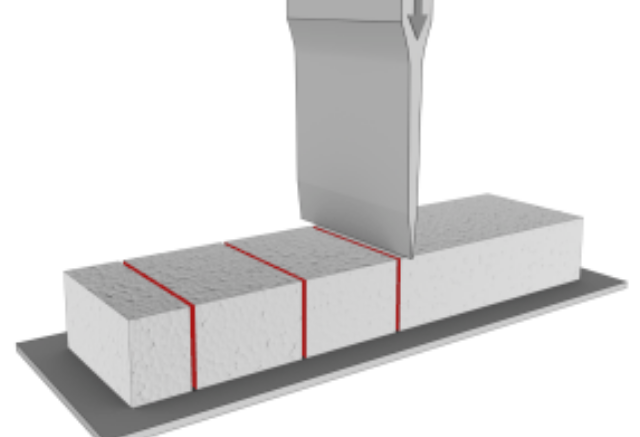

Separation of solid materials:

Using ultrasonic frequency to drive the cutter vibration can easily cut into the material, and it is very accurate and saves material.

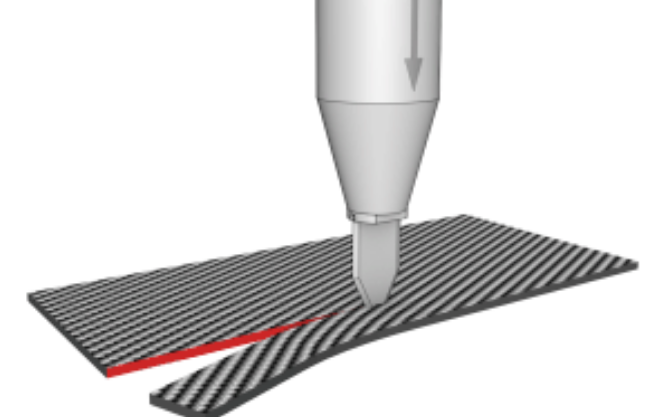

Cutting solid materials:

Ultrasonic vibration will be transmitted by the welding head to the installed cutting blade to cut different materials cleanly, resulting in perfect cut surfaces, such as carbon fiber or rubber products.

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat