Hand-held ultrasonic spot welding machine, pistol-shaped in appearance, easy to operate. It is mainly used for the welding of automobile door panels. Different welding tool heads can be selected according to the welding requirements. It can be used for riveting, welding, embedding, spot welding, vibration drop, etc.

Item No.:

HS-GW35Product origin:

ChinaUltrasonic Assembly Spot Welding System with Gun Type Hand Welder

Description:

The basic principle of ultrasonic assembly is to convert the electrical energy into high-frequency mechanical vibration by expanding and contracting the converter, usually lead zirconate titanate, at the same frequency.This vibration is amplified by a booster and transferred to the workpiece through a shaped tool, or horn, in the form of reciprocating longitudinal motion. Parts being assembled are clamped together under moderate pressure, at which point ultrasonic vibrations force the parts to impact against each other at a preset frequency creating a molecular bond equal to or above the material strength of the parts.

Infinite and accurate combinations of weld time, distance and energy, established through a microprocessor, provide repeatable control of the process, and lend to the full automation of the assembly. Statistical process control and reporting are also possible with some models.

Application :

Simply put, wherever two parts come together and one of them happens to be a thermo plastic resin. Following is a partial list of some of the industries we serve and the typical applications for our process.

• Appliance: Fixtures, hardware, and enclosure assembly, welding of components.

• Automotive: Parts and body components, instrument panels, headlight assemblies, under hood assemblies.

• Cosmetic: Assembly of compacts and other containers, sealing tubes, packaging.

• Electronic/Electrical: Component, connector cable and wire harness assemblies, enclosure cases and instrument faces, audio/video cassette and cartridge, switch assemblies.

• Food: Sealing of pouches, tray containers and fillable fillable tubes; sealing microwavable containers; product packaging.

• Hardware: Product assembly and blister pack packaging.

• Health Care: Product containers and accessories.

• Instrument: Welding and staking case assemblies and face covers.

• Medical: Sterile package sealing; equipment component assembly; syringes and filters.

• Packaging: Welding extruded plastic sheet for boxes/containers, package sealing.

• Textile: Fabric slitting, joining or embossing.

• Toy and Game: Assembly of game elements and product packaging.

Specifications:

|

Item No. |

HS-GW35 |

|

Frequency |

35kHz |

|

Max power |

1000W |

|

Horn |

diameter |

|

Generator |

Digital |

|

External control |

Available |

Advantage:

1. Ultrasonic is the fastest, most repeatable and economical assembly method available to the

industry today.

2. With ultrasonic, most thermoplastics can be assembled without heat, mechanical fasteners, or hazardous consumables such as adhesives or solvents.

3. Ultrasonic can join parts - small or large, simple or complex - with lower reject rates than any other method.

4. Using ultrasonic, labor - both as a skill factor and as a time factor - is significantly reduced. And since the equipment can readily be automated, any non-technical operator can be trained in minutes to produce high volume, high integrity assemblies.

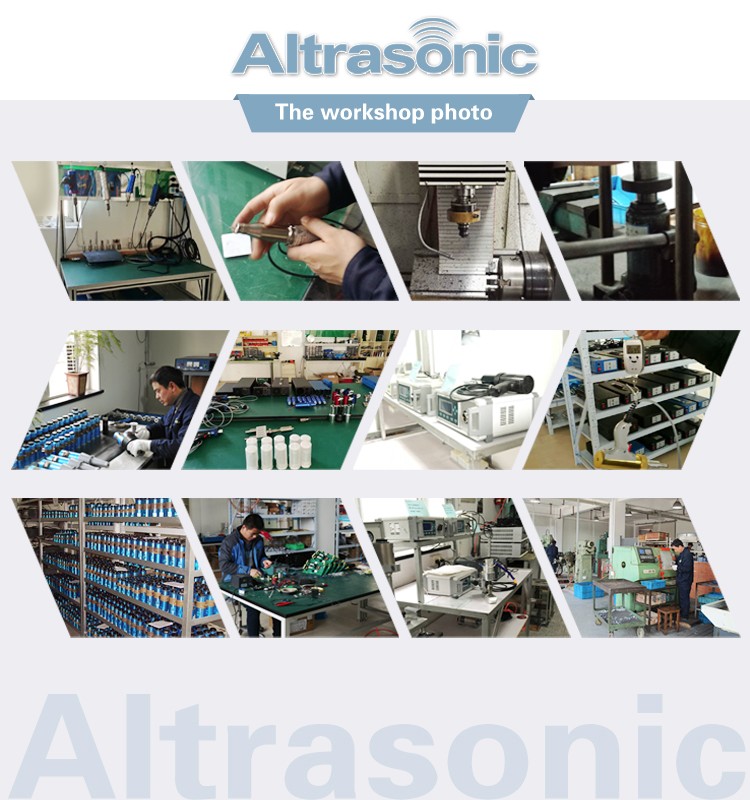

Workshop:

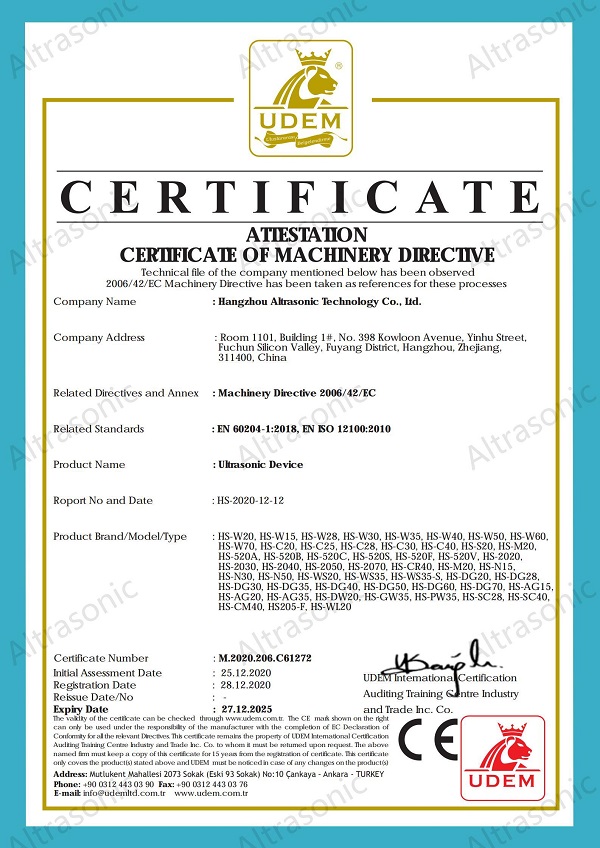

CE:

Packing&Shipping:

Shipping Port:Shanghai

Shipping Term:By express,by air,by ocean and so on.

Leading Time:Quick production leading time and fast delivery.Usually 1-3days if we have in stock.

Payment:

Warranty:

One year Warranty with none human damage.In this period factory will responsible for repair fix it for free or factory will send the new parts to customer instead of the broken parts for free.After warranty time,factory will repair fix it or send the new parts on cost price

Quality control:

3 times old test to confirm the products is well quality.

20 technician work together , and learn together , to improve our products.

48 hours working time to test the stability of our product before sending out.

Previous :

35Khz Ultrasonic Spot Handheld Welder for Welding Shoes FabricNext :

Ultrasonic Spot Welder System 35kHz Puncture Welder with High Power Auto / ManualIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

High Efficiency 28khz Ultrasonic Sealing and Cutting Machine for Plastic Film Packing Bag Read More

Ultrasonic Welding Generator for N95 Mask Making Analog 15k Generator Read More

40kHz 800Watt Ultrasonic Converter BNC Connect Replace Branson 4TH Read More

Processing Special Surface of Mould Amplitude Stability Ultrasonic Milling Equipment Read More

New Product Clothing Manufacturing Rotary Sealing Machine Ultrasonic Sewing Machine Read More

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat