ultrasonic sealing, the heat required for melting is only generated inside the thermoplastic sealing layer. For localized conversion of vibrations to friction heat, the anvil or sonotrode profiles are mostly linear. These profiles ensure focusing of the energy input and therefore short sealing times between 100 and 200 milliseconds.

Product weight:

13kgUltrasonic milk box drink packing welding equipment

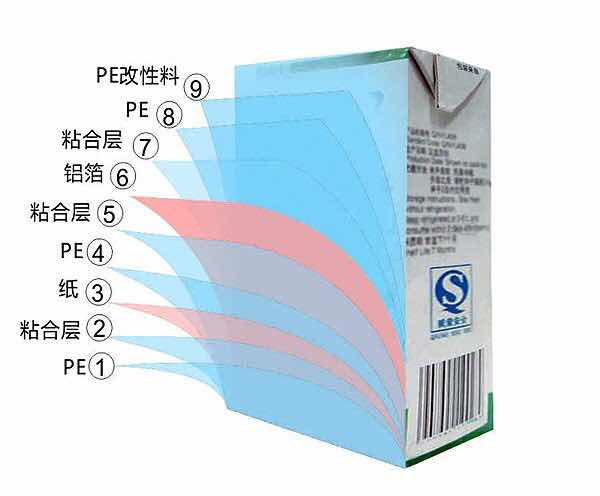

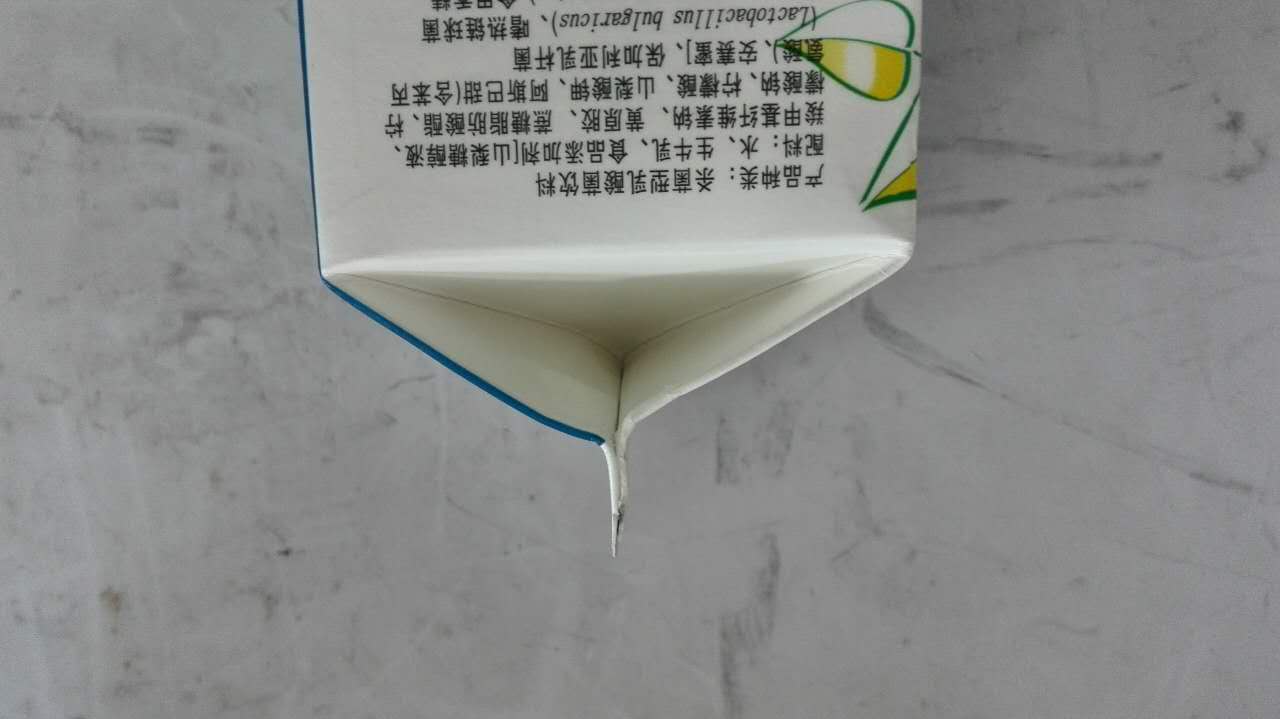

Ultrasonic milk box drink packing welding equipment,With ultrasonic sealing, the heat required for melting is only generated inside the thermoplastic sealing layer. For localized conversion of vibrations to friction heat, the anvil or sonotrode profiles are mostly linear. These profiles ensure focusing of the energy input and therefore short sealing times between 100 and 200 milliseconds. With ultrasonic sealing heat is generated at the inside of the film, not by heat input from the outside as is the case with heat sealing, for example. The tools (sonotrode and anvil) that come into direct contact with the packaging material, remain cold during the entire weld process. The support layer remains almost cold and upon termination of energy input, the heat dissipates faster to the outside due to the temperature difference between the support layer and the sealing layer so that the hot-tack resistance is significantly higher.

Components |

ultrasonic transducer and ultrasonic generator |

Frequency |

15 khz |

Power |

2600w |

Application |

Packing welding |

Operation mode |

Automation |

Materials of horn |

Steel or titanium optional |

Type of horn |

Depending on customer's requirements |

Voltage |

380V / 220V |

Application:

· Thermoplastic films (pouches and bags) Tubes, trays, and cups

· Tubes, trays, and cups

· Cardboard packaging with thermoplastic coating

· Valves and vents on films / filter materials

· Screw caps on coated cardboard packaging / films

Raw material - Bag mouth fold - thermal bonding - side fold - bottom sealing - loop handle fix - thermal bonding - edge cut - bag cut - collection

Principle:

Ultrasonic lace sewing machine used ultrasonic vibration and steel moulds, the above processing will be finished together with pressure.

Advantages:

1. There’s no fog and spark in produce processing, won’t cause damage to fabric edge,

and also can avoid deckle edge.

2. Chang of the ultrasonic cutting die is very easy, and the design of themoulds can

also made according to customer’s requirement.

3. Without pre-heating, and continuous operation is possible.

4. Machines can be combined to one set of equipments in order to sew large width

products once, for instance, guilt cover, gingham, etc.

5. The cutting moulds (cutting die) that be made of special alloy steel which has been

treated with special heat treatment technology, so the moulds with high wear resistance

and gains a longer service life.

Previous :

20Khz Ultrasonic Pistol for Drilling Hole in Fabric with Special Horn and Bottom ModleNext :

20Khz high power Ultrasonic welding equipmentIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

High Efficiency 28khz Ultrasonic Sealing and Cutting Machine for Plastic Film Packing Bag Read More

Ultrasonic Welding Generator for N95 Mask Making Analog 15k Generator Read More

40kHz 800Watt Ultrasonic Converter BNC Connect Replace Branson 4TH Read More

Processing Special Surface of Mould Amplitude Stability Ultrasonic Milling Equipment Read More

New Product Clothing Manufacturing Rotary Sealing Machine Ultrasonic Sewing Machine Read More

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat