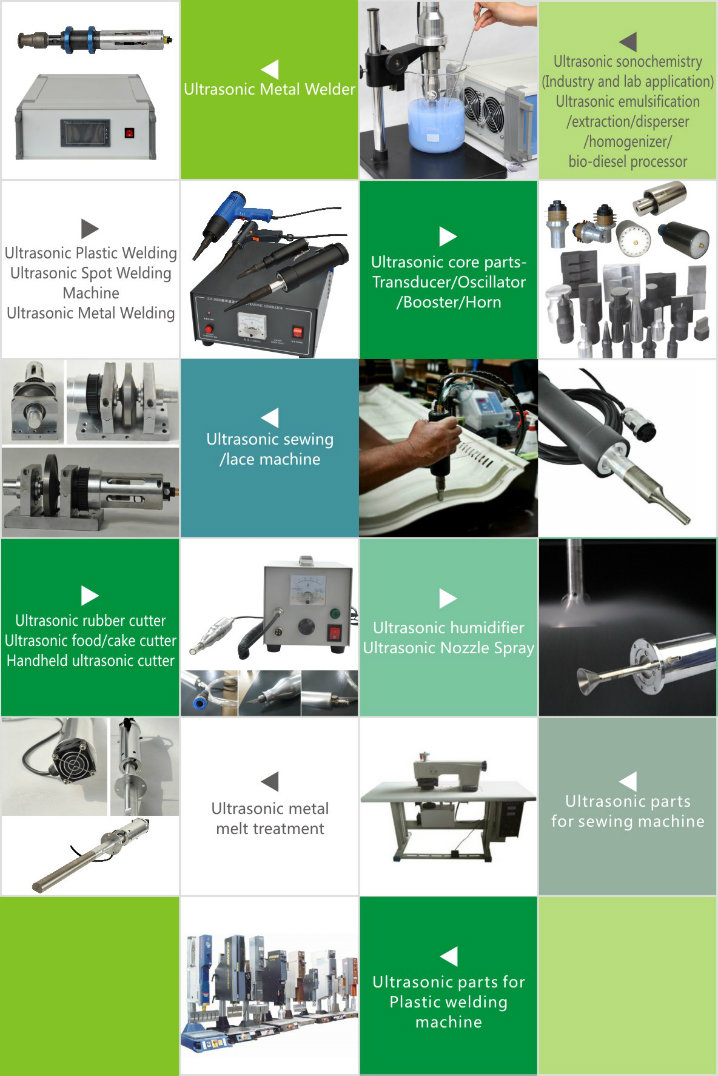

Ultrasonic Dicing For Kinds Material

Product weight:

15gUltrasonic Dicing For Kinds Material

|

Minimum Order Quantity: |

1 Set |

|

Price: |

Ask for quote |

|

Packaging Details: |

Wood case |

|

Delivery Time: |

In 7 Working Days |

|

Payment Terms: |

T/T, WESTERN UNION |

|

Supply Ability: |

100 Sets/Month |

Description:

Dicing with ultrasonic technology has been developed as a new application to support the processing of electronic components (ceramic parts) and optical devices (optical disc parts, optical transmission parts). Using ultrasonic technology will enable the processing of materials such as glass and ceramics, which until now have been difficult to cut with a blade.

| When blade dicing difficult to cut materials such as glass, ceramics, metal and resin, the following issues can occur. |

|

| *1 | The grit on the blade tip wears down and new grit does not become exposed. In this situation, the blade can not process normally. |

| *2 | Workpiece cutting scraps and tape adhesive coat the blade tip and prevent the exposure of the grit. Similar to blade glazing, the blade can not process normally in this situation. |

| *3 | The process current increases even if finer grit is used or the feed speed is increased. An increase in process current can be confirmed by an increase in the spindle current value. |

|

| Dicing with ultrasonic waves has been developed as one countermeasure for blade dicing issues with difficult to cut materials described above. |

Ultrasonic cutting advantage and features:

1.Cut the material quickly and precisely

2.Smooth and traceless cutting edge

3.Powerful, effective realiable

4.Low cost, easy operator. An operator only handle the probe and step the foot switch .So anybody can use it easily.

|

FREQUENCY |

30Khz |

|

POWER |

500W 800W |

|

INPUT |

AC110-240V, 50/60Hz |

|

POWER CONTROLLER |

stepping or continuous |

|

MATERIAL OF CUTTING HEAD |

aluminum alloy, stainless steel, titanium alloy, alloy steel. |

|

MACHINE WIGHT |

4 kg-16KG |

|

ACCESSORIES |

foot switch, additional blade |

|

COOLING DEVICE |

compressed air mouth can be installed. |

|

CABLE LENGTH |

2M or customized |

|

FOOT SWITCH |

available |

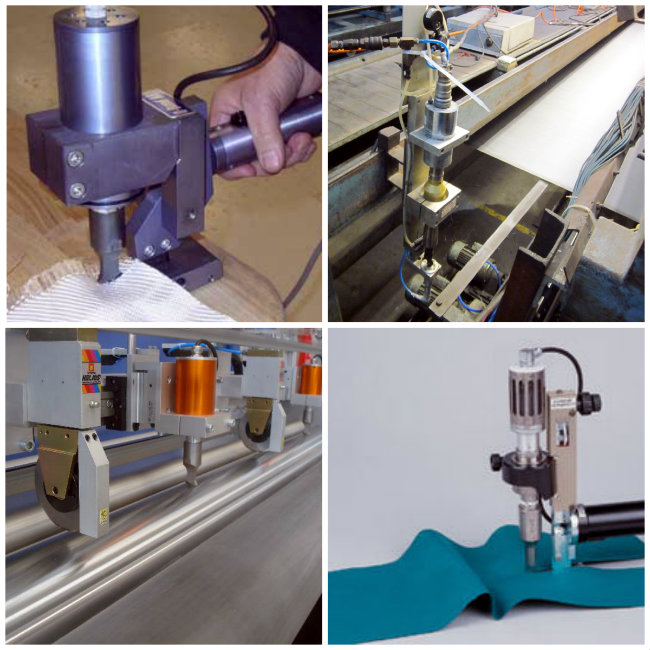

Applications:

1. For thermal plastic gate cutting and flush cutting.

2. For non-woven or woven cutting,textile cutting, fabric cutter, curtain cutting,window blind fabric

3. For rubber, PVC, leather plastic, cardboard, acrylic, polyprolene and so on cutting.

4. For tape and film cutting .

5. For paper cutting,printing industry cutting.

6. For package material cutting

7. For the automotive industry cutting

Previous :

Compact Ultrasonic Hand-held Cutting Unit For Cutting Of Fabrics, Non-woven Materials, FoilsNext :

Ultrasonic Vertical Fabric Cutting MachineIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

High Efficiency 28khz Ultrasonic Sealing and Cutting Machine for Plastic Film Packing Bag Read More

Ultrasonic Welding Generator for N95 Mask Making Analog 15k Generator Read More

40kHz 800Watt Ultrasonic Converter BNC Connect Replace Branson 4TH Read More

Processing Special Surface of Mould Amplitude Stability Ultrasonic Milling Equipment Read More

New Product Clothing Manufacturing Rotary Sealing Machine Ultrasonic Sewing Machine Read More

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat