Transducer For Ultrasonic Auto Plastic Welding

Transducer For Ultrasonic Auto Plastic Welding

|

Minimum Order Quantity: |

10 Set |

|

Price: |

|

|

Packaging Details: |

Foam case |

|

Delivery Time: |

In 7 Working Days |

|

Payment Terms: |

T/T, WESTERN UNION |

|

Supply Ability: |

5000 Sets/Month |

Quick Detail:

Stabilized power and high reliability widely application

Application:

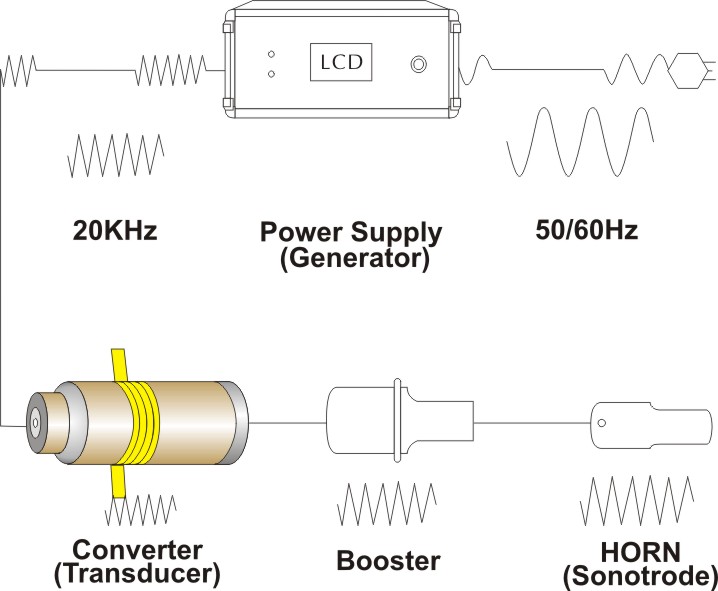

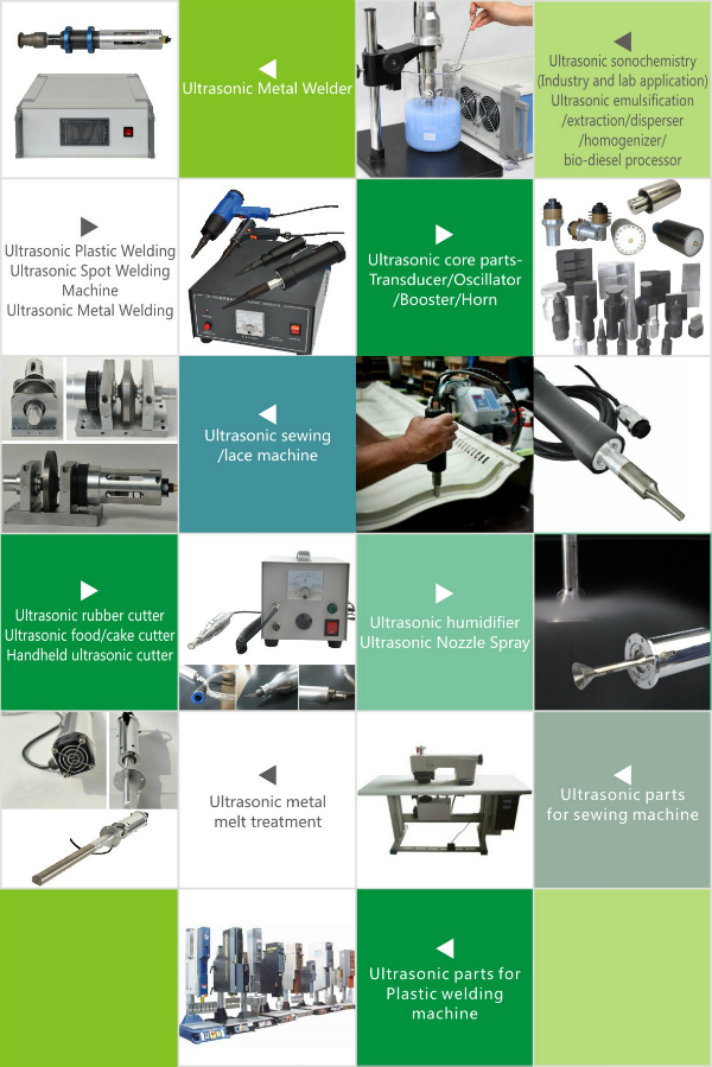

Ultrasonic plastic welding is a kind of thermoplastic jointing technology, which makes use of friction between molecules generated by ultrasonic horn. During ultrasonic welding, two plastic part halves are pressed together under pressure, ultrasonic system transform electric energy in 50/60Hz into mechanical energy in 15KHz, 20KHz, 28KHz, 30Khz, 35Khz, 40Khz by convertor, and strengthens it by booster, then transform the energy to the horn and strengthen it again, then the horn transform it to the plastic part and generate the friction between molecules, by which the temperature at the join increases quickly to melt the plastic material at joining surface. When the melting is enough, ultrasonic stops and keep two plastic being pressed together until the jointing area is re-solidified.It is widely applied in Ultrasonic Auto Plastic Welding.

NTK Type Ultrasonic transducer Main features:

Firstly:Mechanical quality, high efficiency, high in the resonant frequency factor some work can gain the highest electro-acoustic conversion efficiency.

Second, amplitude big: via computer optimization design of structure, vibration amplitude ratio is high, front cover.

Three, large power: in prestressed screw, under the action of piezoelectric ceramic energy get maximum play.

Four, heat-resistant good: resonant impedance small, discusses the small, use temperature range. High reliability life long.

Specifications:

The columnar type NTK TYPE (stabilized power and high reliablity widely application) Item No. Connect screw (Size) Ceramic diameter (mm) Quantity of Ceramic (pc) Resonance frequency (khz) Resistance (Ω) Capacitance Input power (W) Max. Amplitude (um) Yellow Grey Black 7015-4Z M20 X 1.5 70 4 15 15 12500-14000 / 17000-19000 2600 10 6015-4Z M20 X 1.5 or M16 X 1 60 4 15 15 8000-10000 10000-12000 12500-13500 2200 10 6015-6Z M20 X 1.5 60 6 15 15 14000-16000 / 19500-21000 2600 10 5015-4Z M18 X 1.5 50 4 15 15 12000-13000 13000-14300 15000-17000 1500 8 4015-4Z M16 X 1 40 4 15 15 10000-11000 10500-11500 700 8 5520-4Z M18 X 1 55 4 20 15 10000-11000 10500-11500 14300-20000 2000 8 5020-6Z M18 X 1.5 50 6 20 15 18500-20000 / 22500-25000 2000 8 5020-4Z M18 X 1.5 50 4 20 15 11000-13000 13000-15000 15000-17000 1500 8 5020-2Z M18 X 1.5 50 2 20 20 6000-6500 6500-7000 8000-9000 800 6 4020-4Z 1/2-20UNF 40 4 20 15 9000-10000 9500-11000 / 900 6 4020-2Z 1/2-20UNF 40 2 20 25 / 4800-5500 / 500 5 5025-2Z M12 X 1 50 2 25 25 5000-5600 / 7000-8000 500 4 3828-2Z 1/2-20UNF 38 2 28 30 3800-4300 / / 500 3 3828-4Z 1/2-20UNF 38 4 28 30 7600-8500 / 10500-12000 800 4 3028-2Z 3/8-24UNF 30 2 28 30 2700-3100 3400-3800 / 400 3 2528-4Z M8 X 1 25 4 28 30 3900-4300 / / 400 4 2528-2Z M8 X 1 or 3/8-24UNF 25 2 28 35 1950-2200 2200-2500 / 300 3 3030-4Z M10 30 4 30 30 / 6200-6900 / 700 4 3035-2Z 3/8-24UNF 30 2 35 40 2700-3100 / / 500 2 3035-4Z M10 X 1 30 4 35 30 5000-6200 / / 800 3 2535-2Z M8 X 1 25 2 35 40 1900-2200 / / 400 2 2540-2Z 3/8-24UNF 25 2 40 40 / 2000-2300 / 500 2 3040-4Z M10 30 4 40 30 5500-6200 / / 1000 2 3050-4Z M8 30 4 50 30 5500-6200 / / 600 2 1560-2Z M6 X 0.75 15 2 60 60 / / 700-800 100 1 1070-2Z M4 10 2 70 200 / / 350-400 100 1

PS:we can also customize depend on your requirements.

Competitive Advantage:

Higher power

More stable

Longer use life

Imported ceramic chip

Previous :

Hot-Sale Ultrasonic P4/P5/P8 Energy Converter For Cutting/Atomizing/Cleaning/WeldingNext :

5020-4Z Ultrasonic Transducer For Auto-plastic Welding MachineIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

High Efficiency 28khz Ultrasonic Sealing and Cutting Machine for Plastic Film Packing Bag Read More

Ultrasonic Welding Generator for N95 Mask Making Analog 15k Generator Read More

40kHz 800Watt Ultrasonic Converter BNC Connect Replace Branson 4TH Read More

Processing Special Surface of Mould Amplitude Stability Ultrasonic Milling Equipment Read More

New Product Clothing Manufacturing Rotary Sealing Machine Ultrasonic Sewing Machine Read More

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat