ISO30 Ultrasonic Spindle Tool Holder for CNC Automatic Machining Industry

Item No.:

HS-M20Product origin:

ChinaISO30 Ultrasonic Spindle Tool Holder for CNC Automatic Machining Industry

Specification:

|

Frequency |

20 Khz |

|

Output Power |

500 W |

|

Voltage |

220 V |

|

Switch |

Handle or foot switch |

|

Power Adjusting |

Step or continuous |

|

Working Time Control |

24 Hours |

|

Weignt |

30 KG ( Determined by the size of the horn ) |

|

Generator |

Digital Generator |

Technical Parameters:

Product shape: BT40 milling machine handle

Working frequency: 15-21KHz;

Resonance point amplitude: 10um or more;

Speed: 3000 r / min or less

Matching tool: carbide end mill head Φ2-Φ13; disk cutter Φ50;

Power: 500W

Description:

Ultrasonic milling is proved as one kind of effective technology to improve the work ability of Titanium alloy, Aluminum alloy and stainless steel. The ultrasonic milling process has more advantages than traditional milling. Comparing the ultrasonic process effect among steel, Titanium alloy, Aluminum alloy and stainless steel, the most prominent surface quality improvement are Titanium alloy and Aluminum alloy, the most prominent cutting capability improvement is stainless steel, and the most prominent quality improvement in side work piece is steel.

Function:

Ultrasonic vibration during the machining cycle to accomplish rapid material removal, improved surface quality, and maximized tool life.

Other advantages of this process include a superior surface finish and low tool pressure.

Ultrasonic machining provides a number of advantages compared to conventional machining techniques.

Both conductive and nonconductive materials can be machined,

complex three-dimensional contours can be machined as quickly as simple shapes.

Additionally, the process does not produce a heat-affected zone or cause any chemical/electrical alterations on the workpiece surface,

a shallow, compressive residual stress generated on the workpiece surface can increase the high-cycle fatigue strength of the machined part.

Applied for Material:

Hard and Brittle materials:

Dental,zirconia,chrome,cobalt,,titanium,ceramic, gemstones CFRP,glass,bead,optics,sapphire,alumina,ferrite,PCD,piezoceramics, quartz,CVD Silicon Carbide,Ceramic Matrix Composites,Technical Ceramics,tungsten carbide,jewelry.

Competitive Advantages:

Workshop:

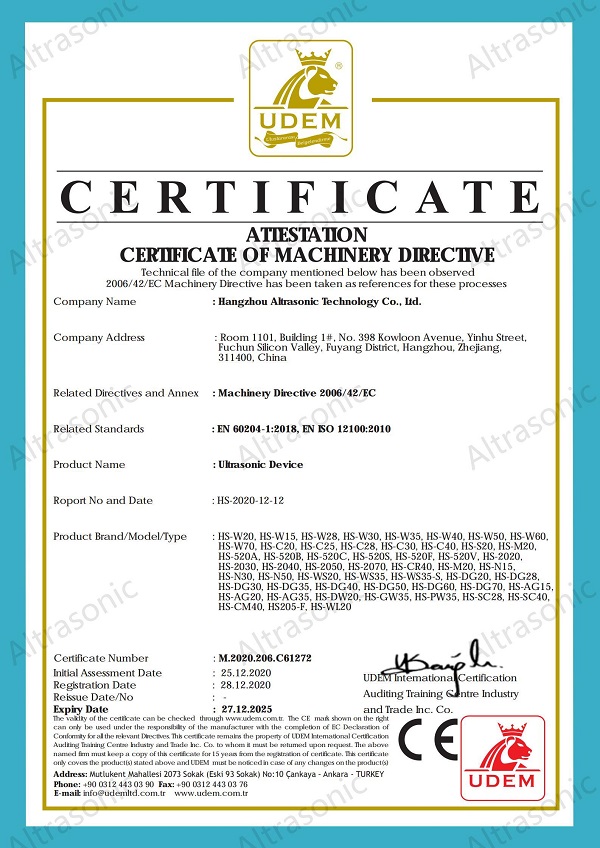

CE:

Packing&Shipping:

Shipping Port:Shanghai

Shipping Term:By express,by air,by ocean and so on.

Leading Time:Quick production leading time and fast delivery.Usually 1-3days if we have in stock.

Payment:

Previous :

Newly Defined Rotary Ultrasonic Machining for dental,zirconia,chromeNext :

BT40 Ultrasonic Spindle Tool Holder for Assisted Machining SystemIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

High Efficiency 28khz Ultrasonic Sealing and Cutting Machine for Plastic Film Packing Bag Read More

Ultrasonic Welding Generator for N95 Mask Making Analog 15k Generator Read More

40kHz 800Watt Ultrasonic Converter BNC Connect Replace Branson 4TH Read More

Processing Special Surface of Mould Amplitude Stability Ultrasonic Milling Equipment Read More

New Product Clothing Manufacturing Rotary Sealing Machine Ultrasonic Sewing Machine Read More

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat