Domestic first intelligent automatic tracking frequency ultrasonic DG series. It uses high-performance microprocessor anti-interference. Realization of electronic manipulation. All welding control parameters are managed by the microcomputer. Intelligent frequency control system, eliminating the inconvenience of manual FM. Sonic overload automatic detection. Tracking real-optimal resonance point. Vibration set temperature remains the lowest point. Frequency welding head temperature changes followed. The machine automatically adjusts to run more stable.

Item No.:

HS-DG-20Payment:

TT, West union, PaypalProduct origin:

ChinaColor:

SilverProduct weight:

10KgShipping port:

Hangzhou

HMI Human Machine Interfaces Configuration Working Method by Ultrasonic Digital Generator

Specifications:

Model |

HS-DG-20 |

Frequency |

20khz |

Output power |

2600watt |

Frequency tuning method |

continue or pulse optional |

Size |

300*450*170 mm |

Input Voltage |

220V/110V 50/60HZ |

Net weight |

6kgs |

Temperature |

≤300℃ |

Moisture |

≤85%RH |

| Power adjustable | 1%-99% |

| Applications | For antenna embedding machine |

Description:

Domestic first intelligent automatic tracking frequency ultrasonic DG series. It uses high-performance microprocessor anti-interference. Realization of electronic manipulation. All welding control parameters are managed by the microcomputer. Intelligent frequency control system, eliminating the inconvenience of manual FM. Sonic overload automatic detection. Tracking real-optimal resonance point. Vibration set temperature remains the lowest point. Frequency welding head temperature changes . The machine automatically adjusts to run more stable.

Applications:

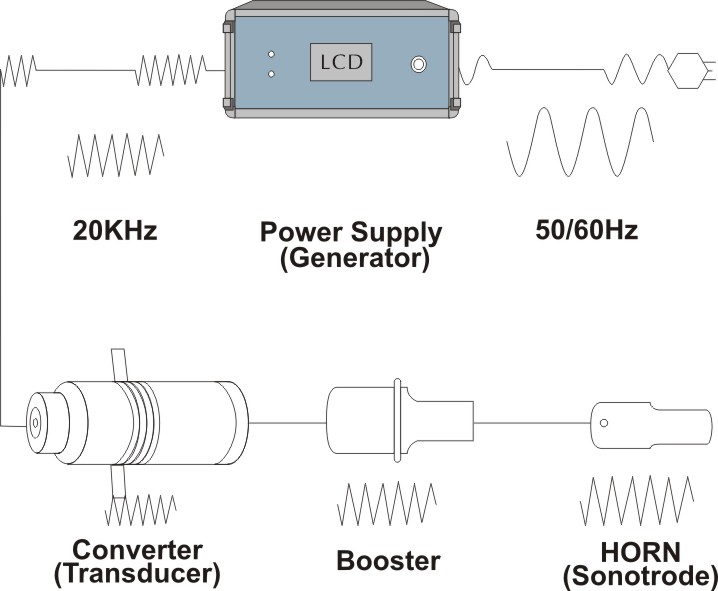

Ultrasonic generator main function is to generate high power and high frequency alternating current, drive the ultrasonic transducer.

Ultrasonic generator is applied to all kinds of ultrasonic equipment, mainly with ultrasonic welding, ultrasonic cutting, ultrasonic chemical equipment and ultrasonic welding equipment such as non-woven fabric.

Full Digital high power -Ultrasonic generators, Ultrasonic horn, ultrasonic sonotrode, sonotrode, Ultrasonic transducer, Ultrasonic booster, Ultrasonics welding, Ultrasonics welding technology, Ultrasonis cutting, Ultrasonics food slicing, Ultrasonics Food cutting, Ultrasonics Metal Welding, Ultrasonics Sealing, ultrasonics packaging, Food-cutting technologies, ultrasonic plastic processing, ultrasonic sealing technology, Ultrasonic power generator

Advantages:

1.High stability: All-digital integrated circuits, use of US imports of high-performance processors interference, while reducing the number of components, simplify the hardware structure, thereby improving the reliability of the system.

2. Automatic frequency tracking: Digital frequency synthesis technology combined with digital phase-locked loop frequency tracking of complex control technology, can eliminate the temperature, static load, machining area, tool wear and other factors drift disadvantages of conventional analog regulator insurmountable, conducive parameter adjustment, easy modification by software, easily adjust the control scheme and achieve a variety of new control strategies.

3. Strong output: The use of IGBT power modules plus his excited oscillation circuit structure, the output power is more than 1.5 times that of conventional self-excited circuit.

4. Amplitude stepless adjustment: Amplitude can instantly increase or decrease in the adjustment process, also can be micro adjusted, can effectively prevent the perfect size pieces of plastic welding, effectively reducing wear shock, burns and so on. Defective amplitude setting range of 10% to 100%.

5. Intelligent three protection and fault alarm:

Diecurrent protection, frequency offset protection, total output is too large to protect. Equipment failure, the generator will stop working, and make the appropriate cause of the malfunction prompts until technician troubleshooting.

6.Intelligent closed-loop amplitude control technology to achieve the amplitude adjustment, independent of input supply voltage and load fluctuations affect the amplitude of the output remains constant.

7. Two kinds of welding mode switch back and forth, so that a higher precision welding, soldering and better results.

Previous :

Ultrasonic welding drive power digital type ultrasonic welding generator for plastic welder machineNext :

High Frequency 70Khz Ultrasonic Digital Generator for Wire EmbeddingIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

High Efficiency 28khz Ultrasonic Sealing and Cutting Machine for Plastic Film Packing Bag Read More

Ultrasonic Welding Generator for N95 Mask Making Analog 15k Generator Read More

40kHz 800Watt Ultrasonic Converter BNC Connect Replace Branson 4TH Read More

Processing Special Surface of Mould Amplitude Stability Ultrasonic Milling Equipment Read More

New Product Clothing Manufacturing Rotary Sealing Machine Ultrasonic Sewing Machine Read More

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat