Assembly Ultrasonic Welding Of Thermoplastics

Product origin:

ChinaProduct weight:

130Kg20KHz Ultrasonic Plastic Standard Welding Machine For Electron,Stationery,Packing Hot Sale

|

Minimum Order Quantity: |

1 Set |

|

Price: |

|

|

Packaging Details: |

Fim |

|

Delivery Time: |

In 7 Working Days |

|

Payment Terms: |

T/T, WESTERN UNION |

|

Supply Ability: |

200 Sets/Month |

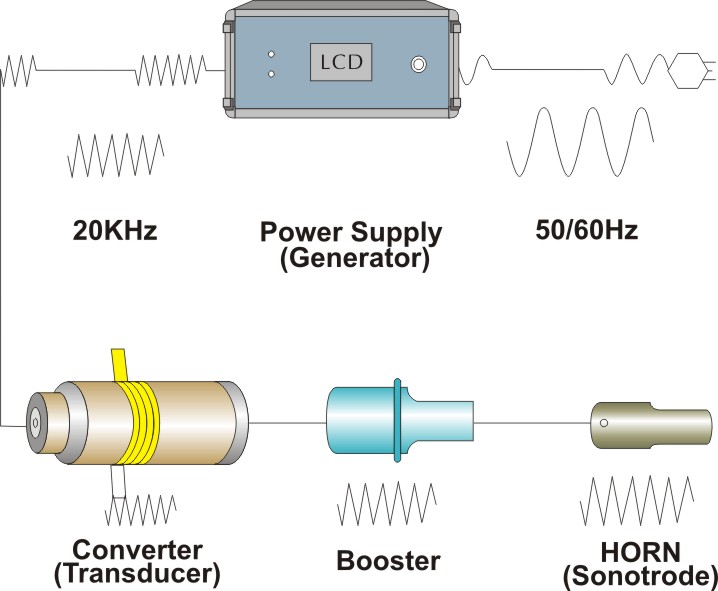

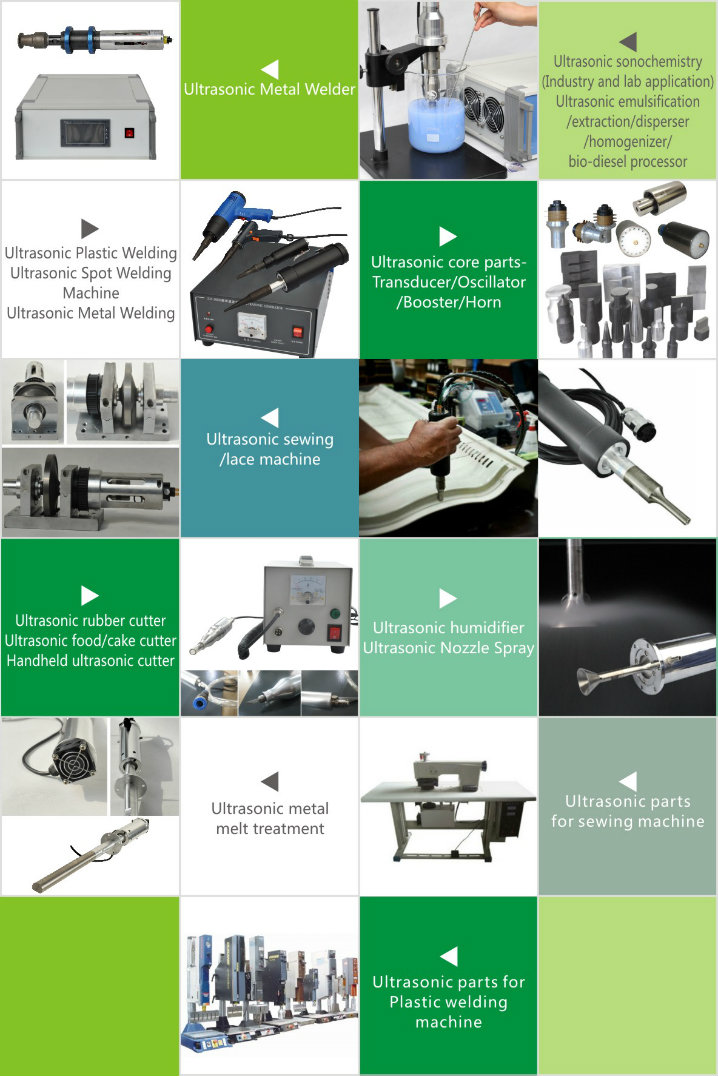

The 20KHz Ultrasonic Plastic Welding Machine is with IC circuit control design, automatic tracking frequency. The ultrasonic plastic welding

machine may be applied in toys, household, electronics, electrical industry, automobile industry...etc.

Features

Works on spot welding and riveting screw.

Don't take much space and easy operation.

Can work independently on assemble on automation as margin unit.

IC circuit control design, automatic tracking frequency.

Overload safe device, quality constant.

Finger touch panel design, adjust time, more accurately.

Easy balance adjustment with high power, can weld big area.

Application

Toys: Remote car & boat, plastic doll, toy gun, water gun, TV game, phone...etc.

Household: Washer balance ring, computer, TV shell, remote unit, steam iron.

Electronics: Cassette case, video case, calculator, disc.

Electrical industry: Connector, transformer, relay.

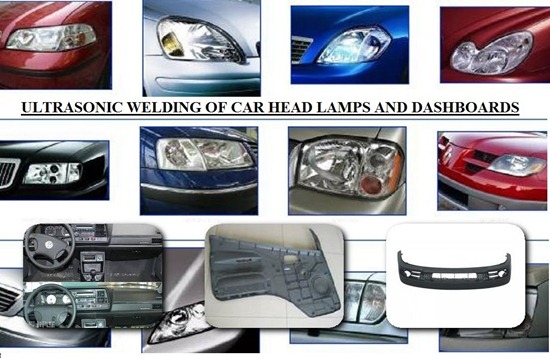

Automobile industry: Head light, tail light, brake light, lunch box, rearview, oil filter.

Food industry: Thermos-bottle, thermos cup, food container.

Stationery: Pencil case, PP file, staple, ink bottle, pen stand.

Other: Christmas decoration ornament, hair decoration ornament, surgery mask.

Manufacturers of underwear, surgical masks, medical shoes and bedcovers, among other segments, have already extensively adopted the ultrasound technology, due to its highly resistant hermetical sealing. This technology presents yet more advantages when compared to the usual sewing methods, such as the joining of different types of materials, strong binding quality, no fiber melting beyond the welding area and a stitchless finishing. This system consumes very little energy on stand-by, does not need any adhesives and can dramatically increase the production capacity.

Packing

The welded parts do not present any rough edges and the process does not exhale any odors or smoke. It allows for the joining of transparent parts without any crystallization mark.

This way, the process can be employed in the manufacturing of packages for food and hygiene products, as well as products consisting of internal subsets.

It also allows for the processing of flammable or explosive products without any risk of ignition or explosion.

The process is also normally executed in one second, without the need for an extended cooling and/or drying time.

Specifications:

|

Competitive Advantage:

★Efficiency: The welding process is very fast, welding time is only 0-999 seconds.

★Strength: Can bear more pressure and tension (the weld joint has same strength as the base material).

★Quality: Finished product is hermetic sealing (airtight and watertight).

★Cost: Non bolt or glue, reduce labor and costs (no adhesives, screws, connective bolts).

★Appearance: The joints are repeatable, clean and precise.

Previous :

20Khz high power Ultrasonic welding equipmentNext :

Assembly Ultrasonic Welding Of ThermoplasticsIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

© Copyright: 2026 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to WhatsApp