Altrasonic is a competent research and consulting company rendering prime strategic market analysis based on diverse segments with the help of authentic database developed by our experts. We provide tailor-made market reports to our esteemed clients in order to help them gain profit in their respective businesses.

Item No.:

HS-Q20Product origin:

ChinaColor:

Green20K Integrated Ultrasonic Plastic Welder with LCD Screen for Baby Diapers

Description:

Ultrasonic plastic welding machine is a high - tech technology for welding thermoplastic products. The advantage of ultrasonic plastic welding is to increase productivity, reduce cost, improve product quality and safety production. Ultrasonic welding equipment can be easily customized to fit the exact specifications of the parts being welded. It is typically used with small parts (e.g. cell phones, consumer electronics, disposable medical tools, toys, etc.) but it can be used on parts as large as a small automotive instrument cluster.

Applications:

Toy industry: such as toy gun, water gun, telephone and rag baby etc.

Electronic industry: The gum case of watch, nylon watch band, calculator, sound box wraps hull, cell phone battery etc.

Car industry: Car light.

Pack an industry: Disguise box, PVC packing box, toothpaste tube etc.

General business ware: The typewriter color take, video cassette rack, tape box, computer disk etc.

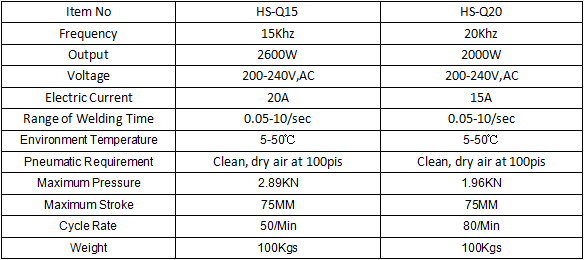

Specifications:

Advantages

It can be applied to miscellaneous combination of material welding and allows welding of thick and thin sections.

Simplified welding of high and heat conduction materials such as copper, gold, aluminum, silver, etc.

he pressures used for welding are low along with low consumption power.

The time taken for welding is less and the width of deformed areas are thinner than that for the cold welding.

Competitive Advantage:

Service: Timely feedback; Free design; 1 year Warranty.

Quality: Full testing before shipping; we reputation from customer.

20K Integrated Ultrasonic Plastic Welder with LCD Screen for Baby Diapers

Workshop:

CE Certification:

Packing&Shipping:

Payment:

FAQ:

1. Can the welding horn be customized?

Yes, we can customized the welding horn according to your request.

2. Are you trading company or manufacturer ?

We are a factory with our own international business department,.Also welcome customer visit our company for experiment.

Generally it is 1~7 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Previous :

Ultrasonic Advanced 20Khz Plastic Welding with High Power 3300w with New TechnologyNext :

20Khz Ultrasonic Continuously Welding by Electric System ControlIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

High Efficiency 28khz Ultrasonic Sealing and Cutting Machine for Plastic Film Packing Bag Read More

Ultrasonic Welding Generator for N95 Mask Making Analog 15k Generator Read More

40kHz 800Watt Ultrasonic Converter BNC Connect Replace Branson 4TH Read More

Processing Special Surface of Mould Amplitude Stability Ultrasonic Milling Equipment Read More

New Product Clothing Manufacturing Rotary Sealing Machine Ultrasonic Sewing Machine Read More

© Copyright: 2024 Hangzhou Altrasonic Technology Co.,Ltd All Rights Reserved

IPv6 network supported

Scan to wechat